Empowering Innovation with Tailored Graphene Solutions

SERVICES

What We Do

Nanotechnology Based Application Development

With Enhancing Nanotechnology, We provide customised solutions in the field of polymers, Electronics, Energy, Automotive, Constructions, Desalination, Paints and coating based Applications.

Customized Form of Nano Materials

We provide customized forms of Graphene, Carbon Nanotubes & Metal Oxide Nanopowder products such as functionalizations, dispersion, Masterbatch to cater for your Industrial Applications

Analytical Services for Nano Materials

We offer quick and accurate analysis related to nanomaterials characterisation such as TEM, SEM, XRD, DSC, TGA, Raman spectroscopy, FTIR Spectroscopy and UV Spectroscopy

Our

Products

Graphene

We are the Graphene Manufacturing company In India. We provide different grades of graphene, based on applications such as battery grade, paints & coating grade, composite grade, dispersions and masterbatch

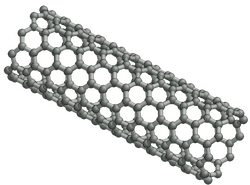

Multiwalled Carbon Nanotubes (MWCNT)

We manufacture various forms of MWCNT, Functionalized MWCNT, MWCNT Ink, MWCNT Dispersion, MWCNT based Polymer and metal nanocomposite.

Metal Oxides Nanoparticles

We Manufacture high quality of metal oxide nano particles such us Zinc Oxide Nanoparticles, Iron Oxide Nanoparticles, Nano Silica, TiO2, Al203, MgO, CuO Nanoparticles.

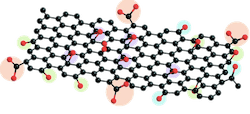

Graphene Oxide

We manufacture various forms of Graphene Oxide, Reduced Graphene Oxide, Graphene Oxide slurry for concrete applications, Graphene Oxide Dispersions, Graphene Oxide & Reduce Graphene Oxide base polymer.

Single Walled Carbon Nanotubes (SWCNT)

Our e-commerce website www.adnanotubes.com to provide Ultra-pure Small Diameter Single-walled Carbon Nanotubes, Metallic & Semiconducting SWCNT.

Conductive Ink

Ad-nano Ink Division provide a high quality stretchable water based graphene conductive ink, solvent based graphene conductive ink, silver conductive ink, graphene coated conductive plastic sheet and conductive fabric.

Nano Materials Dispersions and Coatinge

We manufacture highly stable dispersions and coating of various nanomaterials in many solvents such us water, xylene, IPA, PU, Epoxy, Acrlyic and much more.

Polymer Nanocomposite Masterbatch

We manufacture high quality polymer nanocomposite masterbatch of various nanomaterials with LLDPE, PP, PC, ABS, PA66 and much more

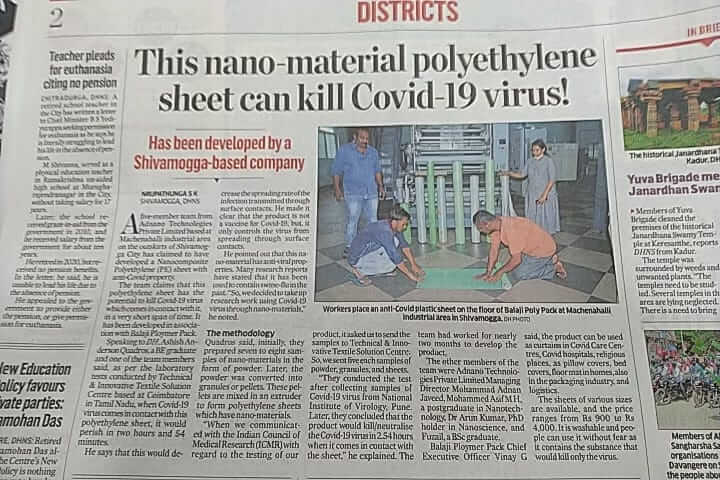

In

News

About Us

Founded in the year 2013, AD-NANO TECHNOLOGIES Pvt Ltd is an advanced nanotechnology-based company in India. We are developing and manufacturing nanotechnology-based applications. Ad-Nano is one of the premier nanomaterials manufacturers and suppliers in India. We are pioneers in manufacturing high-quality graphene products and its various forms. To cater to customers applications, Ad-Nano supplies graphene in bulk quantity at the most optimum price. We are specialized in manufacturing stable nanomaterials dispersions and coating, At ad-nano you will get ready to use dispersed nanomaterials and nanocoating for various applications.

We are a team of dedicated scientists and engineering having huge experience in the field of nanotechnology. We work on the horizon of nanotechnology, with an aim to add nanotechnology to Life. We also conduct our business in a Safe, Ethical, and Environmentally responsible way.

Graphene having enormous potential to spark off the next industrial revolution

Graphene a carbon nano-material is considered to be the world’s strongest material as well as very high thermal and electrical conductivity along with this it is flexible. The cylindrical rolled form of Graphene is a carbon nanotube.

Five Spheres. One Mission.

To be a premier graphene manufacturer and also to add Nanotechnology in life. To understand and cater for the unmet demands of our customers and also conduct our business in a safe, ethical and environmentally responsible way.

Application Development

Optimum Price

Accuracy

Environmentally Safe

Globally Connect

Analytical services

Nano Materials Characterisation Analysis.

We offer quick and accurate analysis related to nanomaterials characterisation at a very optimum price.

TEM

Use to get images of structure upto 10 nm

SEM

Use to get images of structure upto 100 nm

AFM

Use to get image of structure upto 10 nm

XRD

Use to analysis structure of crystalline materials

DSC

Use to measure Tg , oxidation and much more

Raman

Use to provide chemical structure and identity

TGA

Use to determine a material’s thermal stability

FTIR

Use for identification of unknown compounds

UV

Use for determination of different substances.