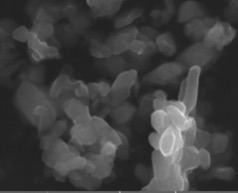

Copper Oxide Nanoparticles

ADCUOWe manufacture Copper Oxide Nanoparticles with multi point of quality check to get accurate CuO Nanoparticles.

| Purity | ~99% |

| Average Particle Size | <100 nm |

| Molecular Weight | 101.96 g/mol |

| Molecular Formula | CuO |

| Melting Pont | 1,326 °c |

| Colour | Black |

| Surface Area | 60-80 m2/g |

| Bulk Density | 0.9 g/cm3 |

Other Forms

We Also Provide CuO Nanoparticles Dispersion in Various Solvents and Resins.

Copper Oxide (CuO) Nanoparticles Dispersion in Water

Get a customized Copper Oxide Nanoparticles Dispersion in Water as per your requirements.

Copper Oxide Nanomaterials Dispersion in DMF

Get a customized Copper Oxide Nanopowder Dispersion in DMF as per your requirements.

Copper Oxide Nanopowder Dispersion in IPA

Get a customized Copper Oxide Nanomaterials Dispersion in IPA as per your requirements.

CuO Nanoparticles Dispersion in Xylene

Get a customized Copper Oxide Nanoparticles Dispersion in Xylene as per your requirements.

Copper Oxide Nanomaterials Dispersion in Acetone

Get a customized Copper Oxide Nanopowder Dispersion in DMA as per your requirements.

Copper Oxide Nanopowder Dispersion in DMA

Get a customized Copper Oxide Nanomaterials Dispersion in solvents as per your requirements.

CuO Nanoparticles Dispersion in Epoxy based resin

Get a customized Copper Oxide Nanoparticles Dispersion in various grades of Epoxy based resin as per your requirements.

Copper Oxide Nanomaterials Dispersion in Poly Urethane based resin

Get a customized Copper Oxide Nanopowder Dispersion in various grades of PU based Resin as per your requirements.

Copper Oxide Nanopowder Dispersion in Acrylic based resin

Get a customized Copper Oxide Nanomaterials Dispersion in various grades of Acrylic base resin as per your requirements.

Customized Copper Oxide Nanoparticles Dispersion

We will undertake customized project to develop Copper Oxide Nanopowder Dispersion as per your requirements.

Advantages of Copper Oxide Nanoparticles

Copper Oxide Nanopowder have increased electrical conductivity, toughness and ductility, increased hardness. Having a narrow bandgap of 1.2 eV and a variety of thermophysical properties is recently attractive in many fields such as energy conversion, optoelectronic devices, and catalysts. CuO nanostructures have other unique magnetic and super-hydrophobic properties.

USES

Applications of Copper Oxide Nanoparticles

Copper Oxide Nanopowder are widely used as burning rate catalysts in rocket propellants. It can greatly improve the homogeneous propellant burning rate, lower pressure index, and perform better as a catalyst for the AP composite propellant. Can be applied to catalyst, superconducting materials, thermoelectric materials, sensing materials, glass, ceramics and other fields. As Ceramic Resistors, Magnetic Storage Media, Gas Sensors, Near-infrared Tilters, Photoconductive and Photothermal Applications. As Semiconductors, Solar Energy Transformation and High-Tech Superconductors.

Space Science

Electronics

Photoelectric

Packing, Pricing & Delivery

Copper Oxide Nanoparticles is supplied in Small Quantity for Researchers and in bulk quantity of Copper Oxide (CuO) Nano Particles to companies and institutes for application developments at the very cheapest price. please contact us for a quote. Our products are packaged in Suitable, Secure, Tamper.

Warranties and Disclaimers

Ad-Nano Technologies Private limited (ANT) warrants that its products shall conform to the description of such products as provided by ANT through ANT’s literature. This warranty is exclusive, and ANT makes no other warranty, like merchantability or fitness for any particular purpose. ANT’s warranties made in connection with any sale shall not be effective if ANT has determined, in its sole discretion, that Buyer has misused the products in any manner. ANT shall not, in any event, be liable for incidental, consequential or special damages of any kind resulting from any use or failure of the products. This product is for R&D use only, not for other uses. Please consult us for safe handling information.