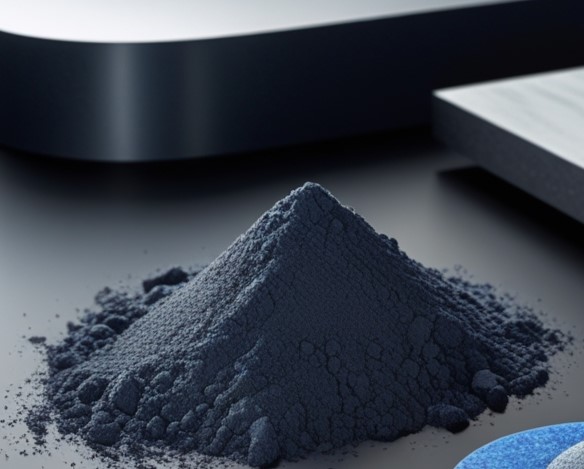

Graphene oxide, a derivative of graphene, has emerged as a remarkable material with a unique structure that offers extensive applications across various fields. Composed of a single layer of carbon atoms arranged in a two-dimensional lattice, the structure of graphene oxide incorporates oxygen-containing functional groups, enhancing its chemical reactivity and versatility. This blog post explores the diverse applications of graphene oxide, highlighting its potential in electronics, energy storage, environmental remediation, and biomedical fields. As interest in this innovative material continues to grow, understanding its properties and functionalities becomes essential for students and the general audience alike.

Properties of Graphene Oxide

Graphene oxide is a comprising graphene sheets with oxygen functional groups bound to the carbon atoms. Its structure includes oxygen-containing functional groups like hydroxyl, epoxy, and carboxyl groups, which enhance its solubility and processability. The distinctive structure of graphene oxide has exceptional properties, it is a promising material for diverse applications in concrete, paints and coating and polymer.

Applications of Graphene Oxide

Concrete

1. Enhancement of Mechanical Properties

Graphene Oxide enhances the mechanical strength of concrete by improving its microstructure. Due to its high surface area and strong interfacial bonding with cement, GO makes better load distribution, increasing compressive and tensile strength. The nanoscale reinforcement prevents crack propagation, leading to higher fracture toughness and improved flexural strength, making concrete more resilient under stress.

2. Improvement of Durability

One of the critical challenges in concrete structures is long-term durability, which is compromised by environmental factors. GO helps by refining the pore structure of concrete, reducing porosity and permeability. This minimizes water absorption and chloride ion penetration, protecting the concrete from corrosion, and freeze-thaw cycles. Additionally, GO promotes better hydration reactions, leading to denser and more durable concrete.

3. Environmental Impact

Adding GO into concrete not only improves performance but also contributes to sustainability. By enhancing strength and durability, GO allows for the reduction of cement usage, which in turn decreases CO₂ emissions from cement production. However, longer-lasting structures reduce the need for repairs and reconstruction, minimizing material waste and energy consumption. This makes GO-modified concrete an eco-friendly solution for modern construction.

Polymers

1. Incorporation in Composite Materials

Graphene Oxide (GO) is widely used in polymer composites to enhance their mechanical, thermal, and barrier properties. Due to the dispersion of graphene oxide in various polymer matrices, GO reinforces the structure by forming strong interfacial interactions with the polymer chains. GO-polymer composites find applications in aerospace, automotive, and high-performance structural materials where strength-to-weight ratio is crucial.

2. Thermal Stability

GO improves the thermal stability of polymers by acting as a heat-dissipating filler. It enhances resistance to high temperatures and prevents polymer degradation by forming a protective barrier against thermal oxidation. This makes Graphene Oxide polymer composites ideal for applications requiring heat-resistant materials, such as fire-retardant coatings, automotive components, and thermal management systems in electronics.

Paints and Coatings

1. Barrier Properties

Graphene Oxide (GO) enhances the barrier properties of paints and coatings by creating a highly impermeable layer that prevents the penetration of gases, moisture, and chemicals. Its layered nanostructure forms a dense network, significantly improving resistance against corrosion, oxidation, and environmental degradation. This makes GO an excellent additive for protective coatings used in automotive, marine, and industrial applications.

2. Scratch Resistance

Incorporating GO into coatings improves scratch and abrasion resistance due to its exceptional mechanical strength. The high surface hardness of GO-reinforced coatings reduces wear and tears. This is particularly beneficial for applications in automotive paints, consumer electronics, and industrial protective coatings where surface durability is essential.

3. Functionalization for Specific Applications

Graphene Oxide can be chemically modified to introduce functional groups that enhance its compatibility with different coating formulations. This allows for the development of specialized coatings with properties such as antibacterial activity, anti-fouling characteristics, UV resistance, and self-cleaning abilities.

Conclusion

Graphene Oxide (GO) continues to revolutionize multiple industries, and its future applications hold potential for advancing technology, sustainability, and performance across various fields. As research and large-scale production techniques improve, GO is expected to become a key material in next-generation innovations. Adnano Technologies has been one of the leading graphene oxide manufacturer and supplier ensuring the highest quality Graphene oxide.

In conclusion, the applications of graphene oxide are poised to significantly impact various fields, ranging from electronics to medicine. Its unique properties, such as large surface area, enable innovative solutions that can address current challenges in technology and sustainability.

For more details on our high-quality Graphene Oxide, visit : Adnano Technologies.